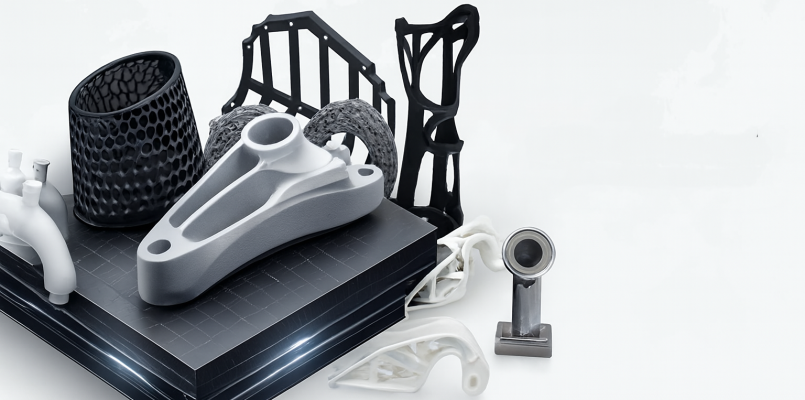

Professional 3D Printing Service

In the field of additive manufacturing, we offer production services with no quantity limit, according to your request.

To contact us to have your desired 3D model produced, simply click the button below and get in touch.

Additive Manufacturing

Our Additive Manufacturing Approach

SEHA Engineering combines its engineering and manufacturing expertise with its in-house polymer-based SLS, SLA, and FDM additive manufacturing technologies, transforming industrial 3D printers to offer professional solutions for functional prototypes and industrial part production.

Our 3D printing infrastructure is structured for the production of complex geometries, rapid prototyping, and engineering-focused applications.

At SEHA, additive manufacturing is not just a production method; it’s an engineering process where design, function, and usage scenarios are considered together.

The selection of 3D printing technologies is made by our expert team, with your approval, based on your criteria such as the mechanical expectations of the part, surface requirements, and intended use. Where necessary, these technologies are positioned to complement each other.

SCOPE OF SERVICE:

- Functional prototype production

- Individual part production

- Production of complex geometries with 3D printing technologies

- Design feedback and manufacturability evaluation

- Pre-series production for R&D and pilot studies

- Guidance and coordination for post-processing (polishing, etc.) processes

APPLICATION AREAS:

Our additive manufacturing and 3D printing solutions are used in the following areas:

- Defense and aerospace R&D projects

- Aviation, R&D and prototyping, and small-scale series production.

- Medical and biomedical R&D and prototyping

- Automotive and industrial equipment

- Fixtures, jigs and auxiliary manufacturing equipment

- University and research projects

- Custom design and engineering applications.

Technologies Used:

SEHA Engineering combines its engineering and manufacturing expertise with its in-house industrial 3D printing infrastructure featuring polymer-based SLS, SLA, and FDM additive manufacturing technologies to offer professional solutions for functional prototypes and industrial part production.

SLS (Selective Laser Sintering)

Thanks to the powder-based manufacturing method, it is possible to produce complex and functional geometries without the need for a support structure. SLS stands out among industrial 3D printing technologies, especially for applications focused on functional use.

The main features of SLS technology are:

- Ability to produce mechanically robust parts

- Suitable for load-bearing and functional applications

- Complex internal geometries and assembled structures

- Stable structure against thermal and environmental conditions

Thanks to these features, SLS is preferred for functional prototypes, mechanical parts, jigs, and fixtures.

SLA (Stereolithography)

Three-dimensional printing systems operating with photopolymer-based production methods enable the creation of highly precise cured structures. This allows for smooth surfaces, fine details, and high geometric accuracy.

Key features of SLA technology include:

- Surface quality and smoothness

- Fine detail and precise geometry production

- Parts with opaque or semi-opaque visual properties

- Part solutions exhibiting flexible or elastic behavior

- Applications suitable for high temperatures or special usage requirements

Thanks to these features, SLA is preferred in visual prototypes, precision parts, design and assembly verification applications, as well as prototype applications used in medical and biomedical R&D studies.

FDM (Fused Deposition Modeling)

Thanks to FDM technology, which operates using a thermoplastic filament-based production method, it is possible to produce prototypes and functional parts quickly and at low cost. Parts with varying mechanical properties can be produced on a large scale using plastic material that is melted and deposited layer by layer.

FDM stands out among industrial 3D printing technologies, particularly for economical prototyping and high-volume part production.

The main features of FDM technology are:

- Low-cost and fast production capability

- Wide range of materials (PLA, ABS, PETG, Nylon, TPU, etc.)

- Suitability for high-volume part production

- Prototypes providing sufficient mechanical strength

- Ideal solutions for assembly, housing, and support parts

These features make FDM the preferred choice for concept prototypes, housing parts, assembly fixtures, large-sized parts, and low-cost functional testing.